You’re not alone—running a manufacturing company is tough

Whether your shop has five people or fifty, chances are you’re wearing more than one hat. Purchasing, production planning, quoting, customer follow-ups… the list goes on. And somewhere in the middle of it all, you’re trying to keep track of spreadsheets, documents, emails, and maybe a few disconnected systems that were never meant to work together.

We’ve been there. As a team with deep roots in manufacturing, we’ve worked inside small factories just like yours. We know how busy days can get and how difficult it is to find the time to step back and fix the very systems that are slowing you down.

That’s why it’s worth asking: Is it time to consider an ERP?

The real cost of disconnected systems

Many small and medium-sized manufacturers run into the same pattern: they start with simple tools—Excel sheets, QuickBooks, maybe a standalone inventory software—and slowly add patches over time.

Eventually, instead of solving problems, these systems become one.

Here’s what we’ve seen go wrong:

- Manual data entry eats up time and leads to frequent errors.

- Teams don’t trust the numbers because systems aren’t in sync.

- Planning becomes guesswork without a real-time view of operations.

- Traceability falls apart when processes happen outside the system.

- High overhead systems bring complexity without improving results.

And in some cases, companies stick with outdated or oversized ERP systems just to avoid the pain of switching—despite constant workarounds, steep learning curves, or rising costs that don’t match the value.

So… what exactly is an ERP?

ERP stands for Enterprise Resource Planning, but don’t let the name fool you—ERPs aren’t just for huge corporations.

An ERP is simply a central system that connects the key parts of your business: inventory, purchasing, production, sales, finance, and more. Instead of jumping between tools or relying on memory and sticky notes, your whole operation runs through one shared platform.

It becomes the brain of your business, helping you:

- Plan production more accurately

- Track orders and materials in real-time

- Manage costs and lead times

- Keep your team aligned and accountable

- Make decisions based on data, not guesswork

ERPs come in all shapes and sizes, from giant platforms used by multinationals to lightweight systems built for small companies. What matters most is finding a system that fits your size and workflow—not the other way around.

Why many small manufacturers hesitate (and why they shouldn’t)

Some companies avoid ERPs because they’ve heard the horror stories—big bills, long implementations, endless training sessions. And yes, some ERPs are built with big businesses in mind. They’re too complex, too expensive, and not worth the squeeze for a company with under 100 employees.

But the right ERP, built for small and medium manufacturers, doesn’t have to be complicated or expensive. In fact, the return on investment can show up faster than expected—especially if you’re currently juggling disconnected tools or doing double work.

With a right-fit ERP, you can:

- Simplify processes instead of adding steps

- Reduce mistakes from manual data entry

- Create useful reports in seconds

- Improve delivery times and customer satisfaction

- Gain traceability without paperwork overload

So where do you start?

Here’s what we recommend if you’re thinking about an ERP—or questioning the one you already have:

-

Assess your current state

Is your team spending too much time tracking down information? Are you duplicating work across systems? Do reports take hours—or worse, don’t exist? -

Talk to other companies like yours

Ask what systems they use, what they like or dislike, and what lessons they learned from past implementations. -

Request demos or trials

Don’t rely on feature lists. Get a feel for the system. See if your team could use it comfortably, day in and day out. -

Avoid overkill

Don’t choose a system because it’s popular in large corporations. Choose one that fits your size, your processes, and your team. -

Plan for change

Any new system will take effort to implement. But with the right guidance and the right pace, it doesn’t have to be painful—and the benefits far outweigh the short-term effort.

Curious if your current ERP is working—or holding you back?

Many companies already have an ERP but still run most of their processes outside the system. That’s a red flag. If you’re not getting meaningful reports, if onboarding new employees is a constant struggle, or if most of your operations still live in spreadsheets… it might be time to rethink things.

We’ve put together a guide to help you evaluate your ERP setup:

Is your ERP implementation successful? Read it here →

Try an ERP that’s actually built for your business

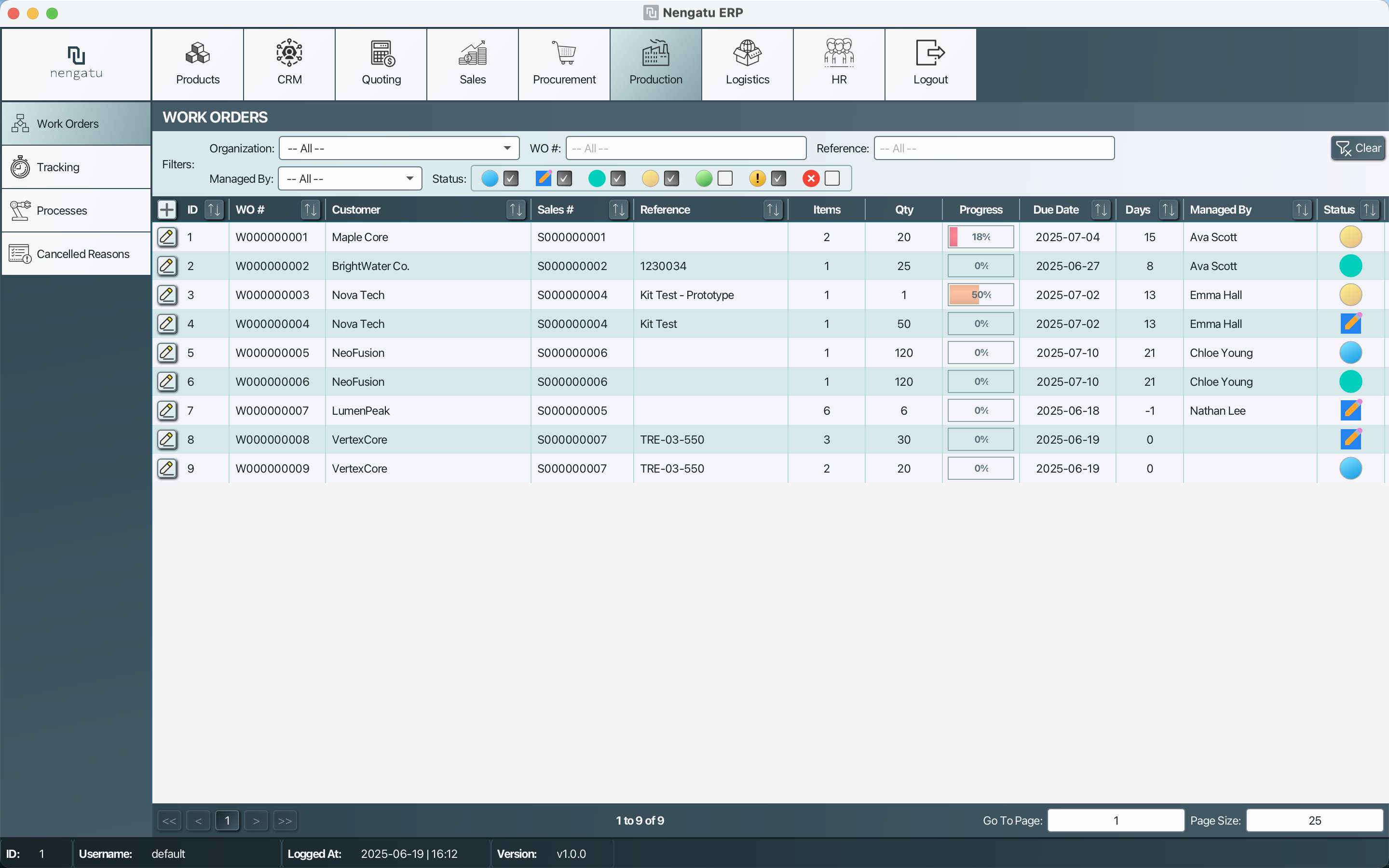

At Nengatu, we built our ERP with small and medium manufacturers in mind. We know the pressure you face—tight margins, tight deadlines, and the need for tools that just work.

We offer a 45-day trial so you can see for yourself how simple and useful the right ERP can be. No risk. No high-pressure sales. Just a clear way to explore what’s possible.

Still unsure? That’s okay.

If any part of this article felt familiar, chances are your current systems may be holding you back.

We’ve also created a 5-part series explaining how to successfully implement an ERP in a small manufacturing environment—whether you’re starting fresh or switching from another system. Start the series here

Change doesn’t have to be overwhelming. With the right plan and the right system, it can actually make your job easier. Let's talk when you're ready.